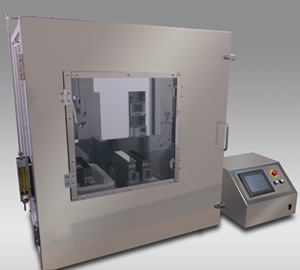

Gas Replacement Box integrated NANO IN COATER (Equipments for Mold Release Agent Coating) NIC-1109G

Small lot production / release agent application device specifications /

This Device is the built-in Equipment by NANO IN COATER (Equipments for Mold Release Agent Coating) and by the Box furnished with the function of gas replacement in between Nitrogen.

This is the Equipment to fix Mold Release Agents on the surface of the working object through the treatments by the process of ultrasonic cleaning for Quartz Glass of maximum 152 mm x 152 mm / t6.0, Coating Mold Release Agent on it, then Rinse Washing and Fixation Drying. Those Treatments are done by every Working Object. This is the dipcoater Type Equipment which is reflected by SDI’s techniques about Dip Coat (Dip Coating).

| Main Specifications | |

|---|---|

| Stroke | 250mm |

| Object Size | 152mm×152mm |

| Object Material | Quartz Glass |

| Dip Speed | from 0.1 mm/sec. to 20 mm/sec. |

| Circulation Device of Coating Liquid | Equipped |

| Temperature Control of Coating Liquid | Not Equipped |

| Filter Mesh | 0.05 micro m |

| Drying Device | Not Equipped |

| Dry Temperature | Not Equipped |

| HEPA (High Efficiency Particulate Air Filter) Unit | Equipped |

| Equipment Dimension (mm) [approximate] | W:800×D:700×H:871mm |

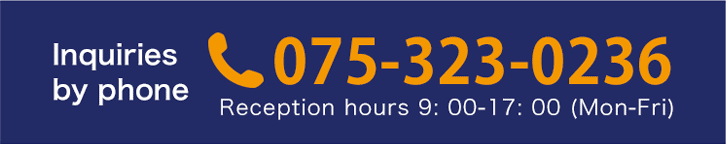

Japanease

Japanease English

English